Perhaps a design flaw of this particular aquarium, more due to it's age than anything else, is the return flow. The returns are 1.5" monsters that can dump water into the sumps faster than they can handle them, but the flow back up, is an anemic 2 3/4" lines per side. This was less of a problem when I ran a pair of Dolphin AmpMaster 3000's, as they had insane head pressure, and would just blast the water through. The COR20's are not as impressive.

Both pumps here are running at 100%. It's pretty anemic IMHO.

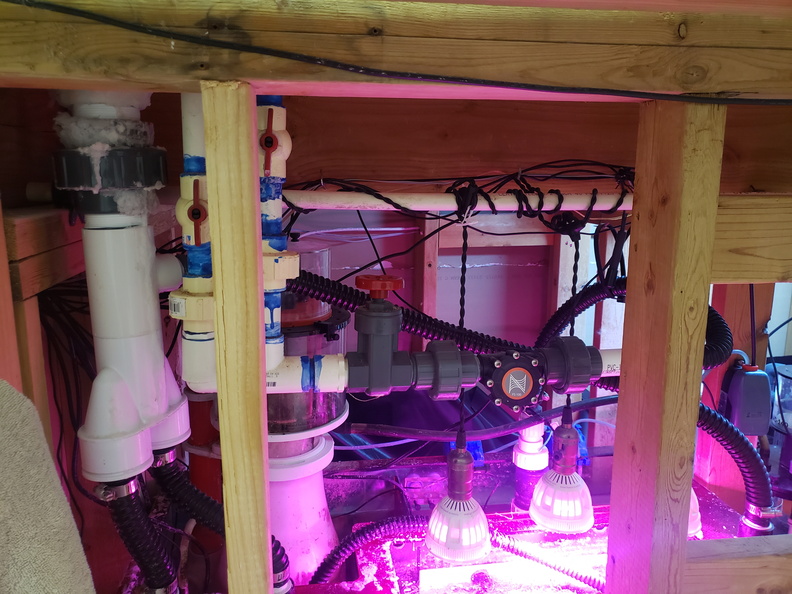

Lets look at the plumbing to learn why:

So, the COR20 feeds to a 1" pondflex, into 1" PVC, to a 1" reducing tee, and then on into a 1" street elbow reduced to 3/4". Inside the overflow, it follows up through 3/4" flexible tubing, and then out through the side of the overflow into the display. On a lark, I decided to calculate the head loss from this, and it came out to around 4000-5000 ft. Insane.

So I needed to set some goals for this plumbing upgrade.

- More flow, less head pressure.

- Designed for a future sump, and retrofitted to the current one.

- Less intrusion into my working area. It's obnoxious trying to get around those cross pipes when working on the skimmer.

- Delete the use of the internal flexible tubing to free those two outputs up for a bean animal overflow.

So it occurred to me, that I could just run up the side of the aquarium, and then over the top of the overflow, and bypass the internal tubing entirely. This launched an idea in my head, so I bought some PVC bits..

And made this:

This is, a 1.25" barb fitting, to Cepex valve, to 2" tee, to FS-200. All built with monstrous 2" pipe, to reduce all restrictions from the additional elbows I'll be putting in. A note on the FS-200 though. Screw Neptune and their insane BSPP threads. I don't know how anyone in Britain has plumbing that doesn't just spew water onto the floor constantly. I tried 2-3 wraps with teflon tape, leaked. A bunch of pipe sealing goop, leaked worse. More pipe sealing goop, no go. Finally, I ended up having to do 10-12 wraps of teflon before the stupid thing stopped leaking. NPT pipe works great with 2-3 wraps. BSPP is a nightmare. Hate BSPP. Stupid BSPP. Booo. Also, cleaning pipe sealing goop out of threads so you can use tape instead is a torture that should be reserved for the deepest pit of hell.

And this:

A 2" to 1.5" adapter, to check valve, to gate valve, to 1.5" -> dual 3/4" barb fitting adapter. I went with the 1.5" tubing here, primarily because the cool adapter at the end was only available in 1.5". It made the gate and check valves alot cheaper too..

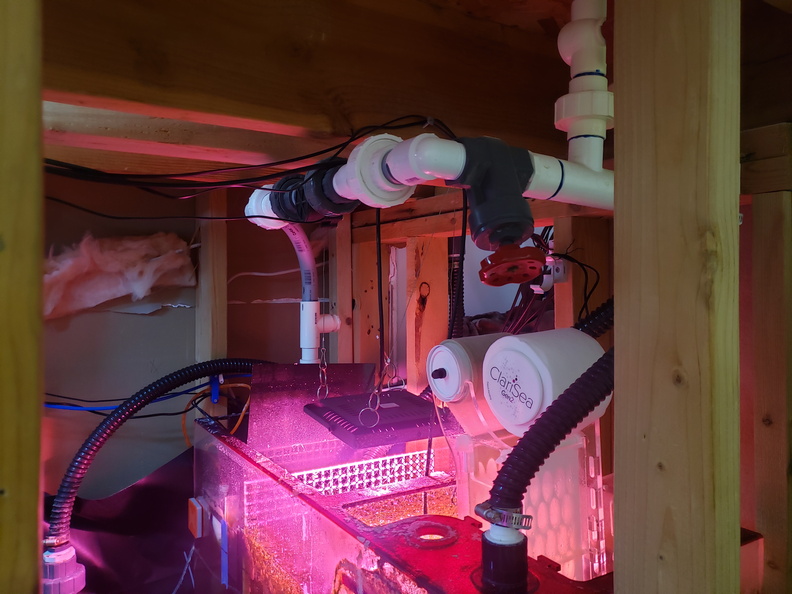

And now installed:

Now this achieves all of my goals. The routing of the pipe is up and out of the way, so it's no longer causing me problems when I try to work on the sumps or the skimmer. I run it into the central chamber, because in an ideal sump configuration, my return pumps would be there instead. It frees up the 3/4" tubes for an eventual bean animal overflow, and it's got much much more flow. How much more flow you ask?

That much more flow. With the pumps running at 60%, not 100%. That net me about 200-250GPH. So why don't I just crank them up to 100%? Well.. math ruins everything.

When the pumps are on, essentially, you are moving part of the water from down in the sump, to up in the display. You basically float a certain quantity up there, by raising the water level in the display over the weirs, so that it can move through them and then back down. How much water? Well, if we raise the display by 1 inch, that's 10' x 4' x 1", or 25 gallons. When I turned on the right side after setting it up, I immediately had to add 3 gallons to the display just to keep the sumps from running dry. Now sure, I could keep cranking up the power and adding water, but eventually, I will add so much, that if I shut the pumps off, the sumps will overflow.

This means, to really get the most out of my new plumbing, I will need new sumps. Which is basically now next on my major todo list, probably in late March to April.

While I was at it with the flow, I needed to correct an issue. Originally, I wired my Tunze Safety Connector into the 6255 on the left side. I tested the snot out of it, and everything seemed to work. 3 weeks ago, I had an actual power outage. Guess what? It didn't work. Turns out, that even with my various tests, when the Apex itself loses power, the Tunze sets itself to zero output. This wasn't the same as just unplugging it from the VDM, or pulling the outlet, the connection did something different.

I was using the 6255 to provide part of the side to side gyre flow, so I couldn't just disconnect it from the Apex, or I would lose that. Luckily, I always need more flow anyhow, so I grabbed a second Tunze Stream 3. I installed this one on the left side, with the flow diverter, in a vertical orientation. I set it to 10 second pulse mode, between 70 and 100%. I really wish they had a longer pulse, but, oh well. This stream is now connected to the safety connector, and when the power goes out, it will provide flow along the top, and hopefully break up the surface to keep everyone alive. It also brings me up to about 16k GPH in the display, which is getting there.. but still not enough. I'll probably throw another WAV on the right side to get into the 20k territory.

With that done, I had one more project to tackle. Another one of the MeanWell drivers for the main LED's was starting to glitch. This is the second one in a month, so that tells me they are nearing the end of their service life. Rather than just keep replacing them one at a time, I decided to swap all 4. This also let me correct yet another historical mistake. Way way back when I built this light, I didn't fully understand the ratings on the COB lights. The seller on ebay listed the light as having a maximum rating of 248W. Obviously I didn't want to max it out, so I got 185w drivers. This was way too much. If I ran them at full, I would burn the COB's out. Now that I'm older and less stupid, I purchased a set of HLG-100-36B's, and now I no longer have to run the VDM ports at 48% to keep from blowing the lights out. 48% wasn't quite perfect anyhow, so I actually gained a few watts of power out of the deal.

And once again, Emperor Angel bless the Anderson Powerpole connectors I used when installing these years ago. I was able to swap the new drivers in with virtually no effort at all.

And as a final capstone, I decided to throw some more fish in the display. I got 4 firefish, and 3 Dispar Anthias (no, I will NOT give up on that dream!). I tossed them in, and everything seemed ok for a bit, and then it went a bit sideways. The male anthias bolted under a rock never to be seen again, and the 2 females went and hid by the cleaning magnet. The 4 firefish though, they seemed fine. My purple firefish however, seemed a little off. He has been the calmest, most peaceful fish I own. When they went it, it set him off. He chased them around a little, and when I left the room for a second, they were nowhere to be seen. This was on Sunday.

After a few days, I basically wrote them off. Doomed from my mistake. The purple firefish was still a bit uppity though, and his swimming range had expanded by at least 2-3x what it was before. And then on Thursday, while feeding, one of the newbies popped up from behind a rock. I peered through a hole in the rockwork, and could see 1-2 more down in there. There is a ton of open space behind my rocks, so plenty of space for fish to hide. This also kind of explains why the purple one has been moving about more, I think he knows they are there, and is keeping watch. I haven't seen them in the last few days, but he is still acting uppity, so maybe that means they are still there? More dither to fix?

I'm kinda hoping this problem is self healing, or that I learn something from it other than "I suck at fish"...

And now, with more flow, and slightly better lighting, I lay my head upon the pillow, dreaming of sump designs that anger me less...